Forever Present Campaign Revives the Iconic ‘A Diamond is Forever’ Tagline

The campaign Forever Present breathes new life into the timeless and iconic tagline “A Diamond Is Forever,” underscoring the perpetual diamond dream

YOU ARE CORDIALLY INVITED TO JOIN US AT THE GEMGENE’VE SHOW 2025

MID’s exhibition booth (E-33) will be greeting buyers from all over the world. MID House of Diamonds will be among the exhibitors at the GEMGENÈVE SHOW.

Come say Hi at Booth: E-33.

MID House of Diamonds will be among the exhibitors at the June 2020 JCK Vegas Show. Come say Hi!

Lorem ipsum dolor sit amet conse ctetur adipisicing elit.

Ipsum dolor sit amet conse ctetur adipisicing elit, sed do eiusmod tempor incididunt.

Dolor sit amet conse ctetur adipisicing elit, sed do eiusmod tempor.

580 5th Ave #3003, New York, NY 10036

+1-212-391-1121

+1-877-391-1121

Blog

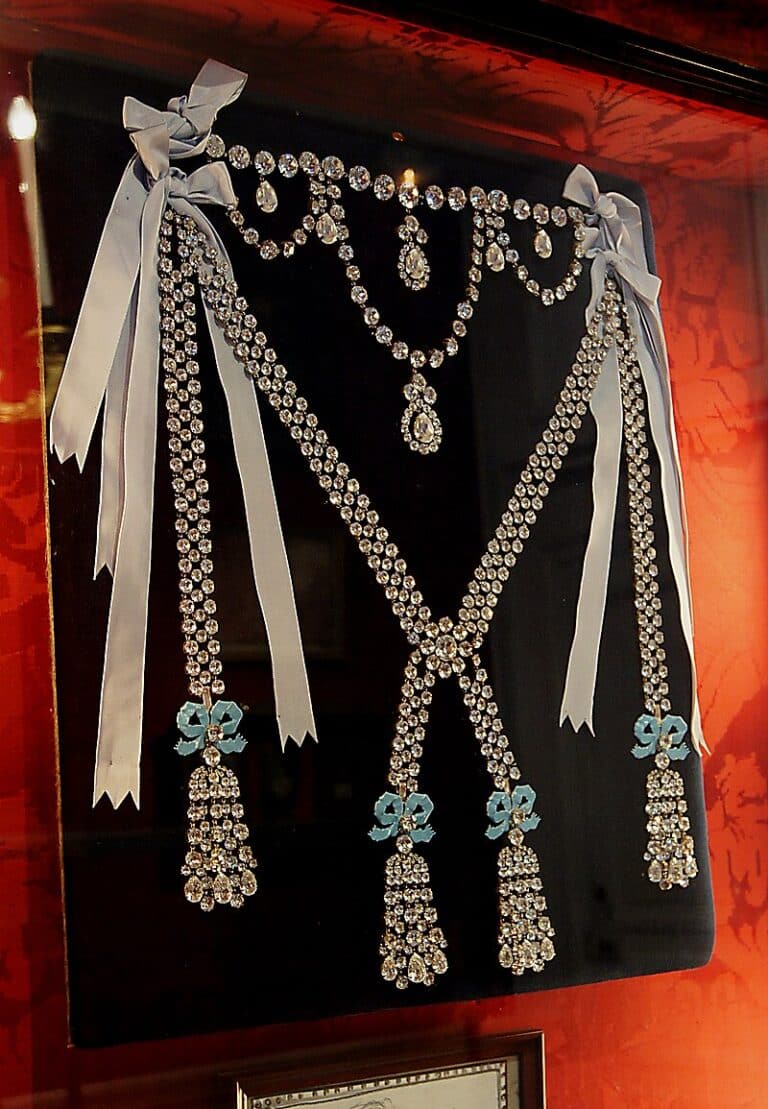

Home » Diamonds blog » Famous Necklace scandal

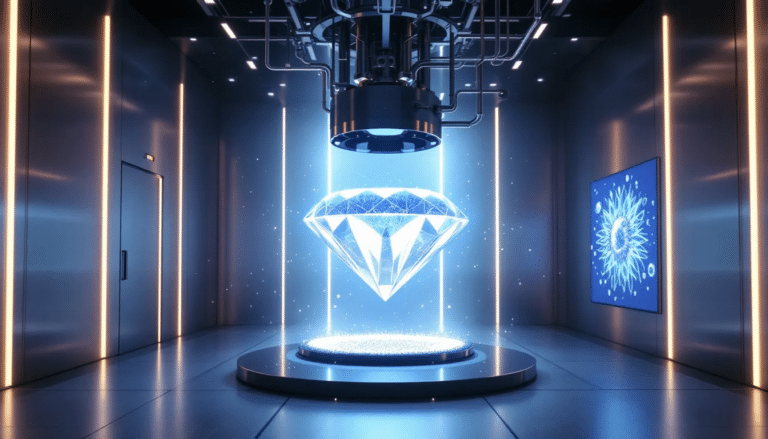

Advanced technologies are transforming diamond processing. From lab-grown diamonds to AI grading and blockchain, these innovations enhance efficiency and sustainability. This article explores how innovation in diamond processing—how advanced technologies are transforming the industry—is reshaping the industry.

Advanced diamond synthesis methods, particularly HPHT and CVD, are transforming diamond creation and application, producing gems with properties comparable to natural diamonds.

Precision cutting technologies, including laser and waterjet cutting, enhance the quality and efficiency of diamond manufacturing, supporting the production of high-value gemstones.

Blockchain and AI technologies improve transparency, grading accuracy, and customer experience in the diamond industry, while promoting sustainability through efficient resource management and renewable energy integration.

The advent of lab-grown diamonds marks a significant shift in the diamond industry. The primary methods for synthesizing these gems are HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition). Each method has its own unique process and benefits, contributing to the diverse applications of lab-created diamonds.

CVD diamonds are created in a vacuum chamber where carbon-rich gases are activated to deposit carbon onto a diamond seed layer by layer. This method is known for producing diamonds with high optical clarity and thermal conductivity, making them suitable for various high-tech applications. CVD technology is continuously evolving, aiming to enhance the efficiency and quality of the diamonds produced.

On the other hand, HPHT diamonds are formed by mimicking the natural conditions under which diamonds are created in the earth’s mantle. This method can produce a range of colors, including fancy colors, by adjusting the conditions during the diamond’s formation. The growth speed of HPHT diamonds is generally faster than that of CVD diamonds, allowing for quicker production.

Both methods yield diamonds that possess the same physical and chemical properties as natural diamonds, making them equally durable and valuable.

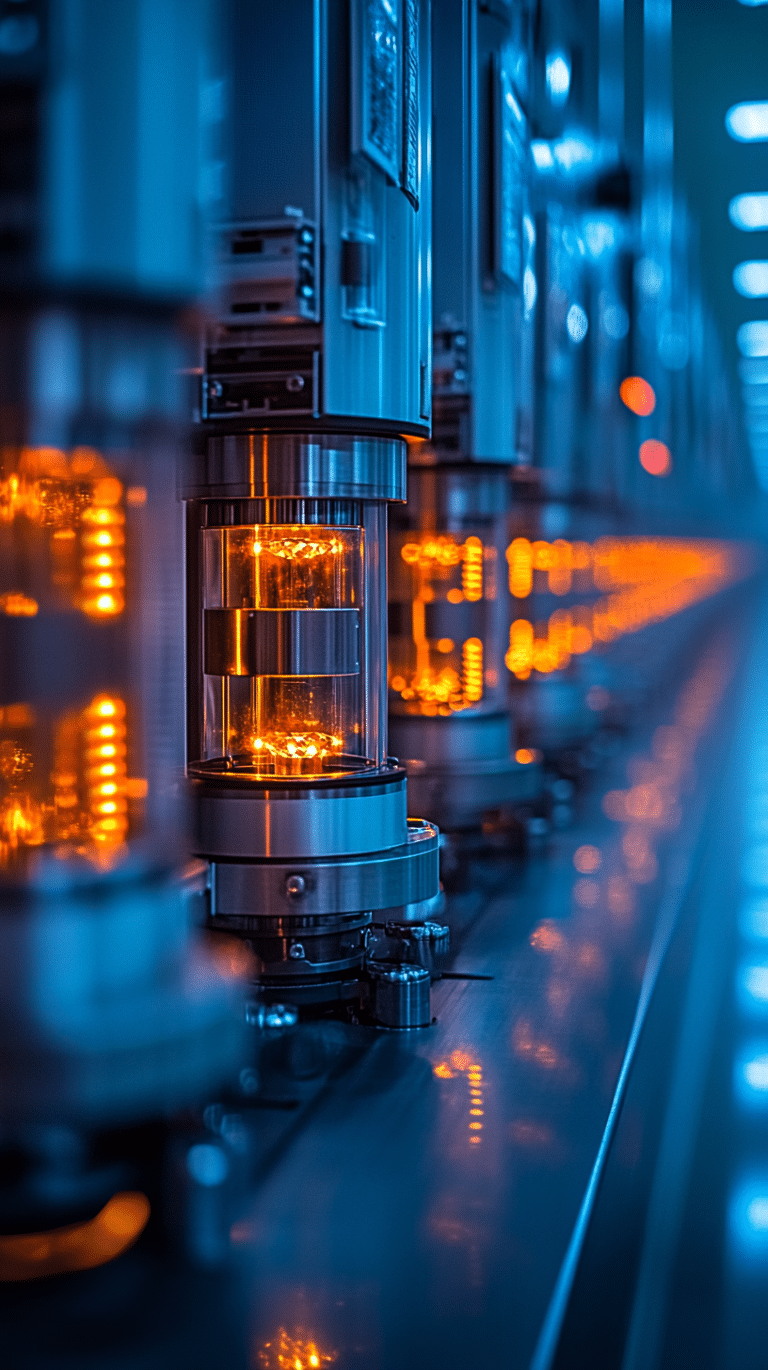

Laser cutting technology has become a cornerstone in the diamond manufacturing process. High-powered lasers enable diamond cutters to achieve ideal symmetry and proportions in gemstones. This technique is known for minimizing material loss, thus optimizing the diamond material used during cutting.

The precision offered by laser cutting significantly enhances the overall quality of the diamonds, making it a preferred choice for manufacturers aiming to produce high-quality gemstones. Besides improving accuracy, this technology reduces waste, contributing to more efficient and sustainable manufacturing.

Waterjet cutting employs a combination of high-pressure water and abrasive materials to shape diamonds with remarkable precision. Waterjet sawing allows for intricate cuts essential in producing finely detailed jewelry pieces.

The high-pressure stream of water mixed with abrasives is particularly effective in achieving precise cuts, making it a valuable tool in the diamond manufacturing process. This technique ensures even the most challenging shapes are accurately achieved, enhancing the overall quality and appeal of the finished jewelry.

Blockchain technology is playing a pivotal role in ensuring transparency and accountability across the diamond value chain. Blockchain provides a transparent, immutable ledger that enhances traceability and significantly reduces fraud and human errors common in traditional systems. This technology allows for the creation of a unique digital identity for each diamond, accessible to all stakeholders in the supply chain, thereby building trust in the data.

Collaboration between luxury brands and blockchain technology addresses ethical concerns, particularly related to conflict diamonds. By ensuring that every step of a diamond’s journey is documented and immutable, blockchain helps in promoting ethical sourcing and reducing the occurrence of conflict diamonds in the market.

Artificial intelligence is transforming the customer experience in the diamond market. AI empowers consumers by providing knowledge that aids in better purchasing decisions. Tools like Rosi offer tailored recommendations without the pressure of sales tactics, enhancing the overall buying experience.

AI-driven solutions surpass traditional methods and offer a more personalized experience for consumers. AI enables the diamond industry to deliver higher service levels, ensuring customers feel confident and informed in their purchases.

Precision cutting is an essential aspect of diamond manufacturing, as it directly impacts the quality and value of the final product. Modern technologies have significantly improved the processes involved in cutting and polishing diamonds, aiming to optimize the 4Ps: Planning, Proportion, Precision, and Polish.

The introduction of advanced tools such as Helium 3D scanners and laser systems like Iklwa/Patara has revolutionized diamond cutting. These innovative technologies provide exceptional control and accuracy, ensuring that each diamond is cut to perfection.

Automation has significantly improved the traditional method of blade sawing in diamond processing. Automated blade sawing boosts productivity and ensures consistent cuts, which is vital for high-quality diamond shapes.

The integration of automation not only optimizes production but also maintains uniformity in cuts. This consistency is crucial for producing diamonds that meet the high standards of quality required in the industry. Automation allows manufacturers to produce diamonds more efficiently while ensuring each gemstone meets desired specifications.

Digital grading systems have revolutionized diamond evaluation. AI technology helps minimize human error in diamond grading, leading to a more standardized and transparent evaluation process. This advancement allows laboratories to grade more diamonds in a shorter period, enhancing overall efficiency.

While AI-driven grading systems provide consistency and reliability, human expertise remains crucial for assessing the unique characteristics of each diamond. The combination of AI and human graders ensures that diamonds are evaluated accurately, maintaining the high standards of quality expected in the industry.

The future of the diamond industry is bright with the ongoing technological revolution. The production capacity of synthetic diamonds is expected to increase, driven by continuous advancements in the lab grown diamond industry to meet rising market demand.

Technology is fueling innovation, sustainability, and market growth in the diamond industry. Integrating diamond-based technologies promises revolutionary advancements in sectors like telecommunications and quantum computing, highlighting technology’s significant future role in the diamond business and among diamond dealers within the diamond pipeline.

In summary, technological advancements are driving a new era in the diamond industry. From advanced synthesis methods and precision cutting technologies to AI-driven grading systems and blockchain for traceability, these innovations are setting new standards in diamond processing.

As we look towards the future, the integration of sustainable practices and cutting-edge technologies will continue to transform the industry, providing consumers with high-quality, ethically sourced diamonds. The diamond industry’s commitment to innovation ensures a bright and sustainable future for all stakeholders.

In summarizing the tale of the infamous necklace, one cannot help but reflect on the interplay of perception, power, and the precipitous fall of a monarchy. The necklace, a masterpiece of luxury, became an emblem of the systemic issues plagizing the French monarchy and a catalyst for the French Revolution. Marie Antoinette, a queen beset by scandal and intrigue, remains a figure of fascination, her image shaped by the unfortunate events surrounding a piece of jewelry she never desired. The diamond necklace affair, with its complex web of deceit and dramatic revelations, serves as a poignant example of the destructive power of rumors and the volatility of public opinion.

The legacy of the necklace lives on, a reminder of the dangers posed when luxury and power become disconnected from the realities of the common people. It is a story that resonates with timeless themes: the pursuit of wealth, the consequences of deceit, and the fragile nature of reputation. As we close this chapter of history, we are reminded that the echoes of the past continue to inform our understanding of the present, shaping our perceptions of leadership, privilege, and the delicate balance between appearance and reality. Let this account of the diamond necklace affair serve as both a lesson and a warning, a narrative that still holds relevance in our modern world.

VP Of Online Marketing - MID House Of Diamonds

The campaign Forever Present breathes new life into the timeless and iconic tagline “A Diamond Is Forever,” underscoring the perpetual diamond dream

Advanced technologies are transforming diamond processing. From lab-grown diamonds to AI grading and blockchain, these innovations enhance efficiency and sustainability. This article

The famous necklace of Marie Antoinette: A Detailed Account symbolizes one of the most notorious scandals in history. This detailed account explores